ABS/USCG/PAM Package Completed for 120-Member Crew of Floating Production Platform Operating in Gulf of Mexico

April 1, 2020

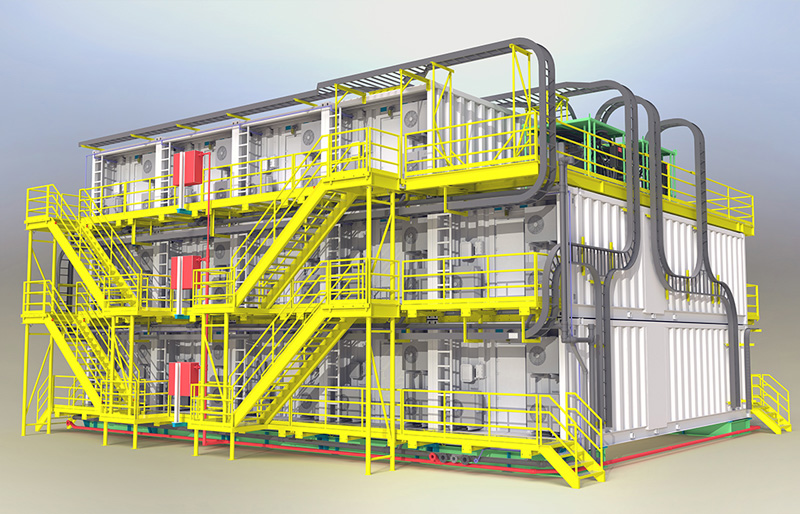

BROUSSARD, La. — HB Rentals has completed the engineering, factory acceptance test and delivery of a fourteen-module ABS/USCG/PAM temporary living quarters package. The package will support a floating production platform, operating in the Gulf of Mexico, by providing living and office space for a 120-member supplemental crew.

Our client needed to accommodate an additional 120 personnel over a six-month period in order to oversee the commissioning of a floating production platform in the Gulf of Mexico. The package required temporary living quarters along with additional office and meeting space for the supplemental crew. Since the installation location was a floating production platform, it required that the quarters be ABS/USCG/PAM certified.

HB’s operations and in-house engineering departments designed and proposed a complete solution that provided the requested living, office, and meeting spaces.

Temporary Living Quarters Package

- Twelve 10-person sleeper modules, each containing 10 beds and 2 bathrooms, with personal storage space for crew members

- One office module for additional workspaces

- One conference module for meetings

- Two custom 300kVA transformer/distribution skids

- Upgraded HVAC systems for Class I Div II compatibility

- Custom blast plates, exterior doors and blast valves to withstand up to a 0.5 bar blast

After being awarded the contract, HB’s in-house engineering team worked closely with the client’s engineering team. Over a two-year period, all the requirements demanded of installing temporary living quarters aboard a floating production platform were met. In addition to the full complement of drawings for all building systems, HB’s engineering team provided the structural analysis of the modules for lift, transport, blast and in place operating conditions in order to meet the client’s and the ABS regulatory requirements. Calculations were also provided for utilities requirements including hydraulics, ventilation, HVAC, power, lighting, as well as fire and gas. Finally, the engineering and design team also worked with the client to provide comprehensive handling and installation procedures.

Factory Accceptance Test

A Factory Acceptance Test was performed at HB’s Broussard facility two months prior to the delivery date.

- The operations team stacked and connected the equipment, duplicating the install on the floating production platform.

- The client and HB’s operations manager inspected the entire package and function-tested all the equipment to ensure all the equipment was working correctly. Find out more about HB Rentals’ Factory Acceptance Test.

- After FAT completion and the client acceptance, the equipment was dismantled and tagged for easier installation on location.

- Equipment is now in transport to the platform where the client would install the equipment.